Description

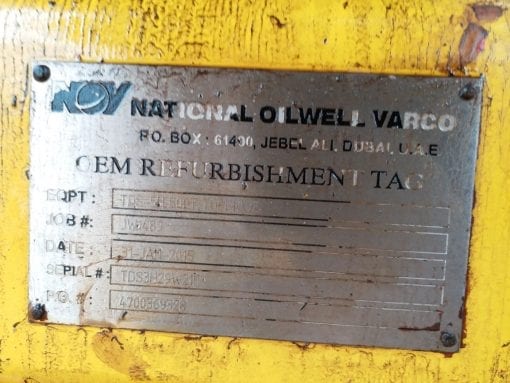

Equipment Name: NOV TDS-5H 500 Ton Top Drive (Used)

Equipment Location: India

Manufacture Year: Refurbished 2015

NOV TDS-5H 500 Ton Top Drive Information

Model Number: NOV TDS-5H 500 Ton

Pressure Rating: 1300 HP

Loading Capacity: 500 Tons

The NOV TDS-5H 500 Ton Top Drive is a portable top drive designed for land-based drilling operations.

A NOV TDS-5H 500 Ton Top drive is a mechanical device on a drilling rig that provides clockwise torque to the drill string to drill a borehole. It is an alternative to the rotary table and kelly drive. It is located at the swivel’s place below the traveling block and moves vertically up and down the derrick.

A top drive is comprised of one or more electric or hydraulic motors, which is connected to the drill string via a short section of pipe known as the quill. Suspended from a hook below the traveling block, the NOV TDS-5H top drive is able to move up and down the derrick. Many times, slips are still employed on a rotary table to ensure the drill string does not fall down the well.

NOV TDS-5H 500 Ton Top Drive Benefits

- A NOV TDS-5H 500 Ton Top Drive is capable of drilling with three joints stands, instead of just one pipe at a time.

- Top drives typically decrease the frequency of stuck pipe, which contributes to cost savings.

- Top drives are also preferable for challenging extended-reach and directional wells

- A top drive allows drillers to more quickly engage and disengage pumps or the rotary while removing or restringing the pipe.

- The lift can be operated hydraulically to move toward the staple, and so he can maneuver the drill pipe and Drill Collars safely, this reduces the risks in handling the pipe.

- It is equipped with a valve to dial, remote control operated, which reduces the loss and leakage of drilling mud when the reviews coming out or is disconnected after driving over the rig floor.

- In the well control operations, with the top drive shaft increases security by reducing wear on the blowout preventer to allow the seal around a round tube rather than around a quadrant or hexagonal kelly. You can connect to the drill pipe at any level of the tower to circulate the drilling fluids.

- If wellbore stability allows, you can make connections in the background during directional drilling, eliminating the need to re-orient the directional tool face after each new connection

- Reduce costs by streamlining the drill: NOV TDS-5H 500 Ton Top Drive eliminates downtime caused by the difficulty of putting the bushing of the rotary dial. In travel is eliminated and time required for the swivel and kelly back in its holster.

- It reduces the time for those functions that are not drilling. Most of the time remains drilling. Less time on the connections, travel, taking directional records, reviewing, etc.

- Rotation and continuous circulation during the movement of the drill string, the most important feature in the top drive drilling, and pumping capacity to rotate continuously while-putting reviews or reviews, out of the hole. Only where necessary continuous rotation can be applied to traffic while entering or leaving the hole with the drill string in directional or horizontal wells. Reduce friction between the drill string and the walls of the hole, and in the case of probable landslides packaging effectively remove the effect of rotation and movement.

- Reduce risk and total drilling costs by minimizing the problems of differential sticking Grips and packaging. The cost of downhole tools that may be lost in the well are high.

- Drill holes in the pipe and move bars (3 tubes) reduced significantly the time of directional orientation after each connection while doing directional drilling with downhole motor. Continuous cores can be cut 60 or 90 feet.

- Applies the back reaming without limitations. This maneuver with kelly and wedges present a hazard to personnel maneuvering tools.

- NOV TDS-5H 500 Ton Top Drive is a more secure and easier to implement, simultaneously, torsion and tension that is required in point operations free and loosened the string.

- Use more efficient procedures and successful background in fishing activities, including the use of “overshot”, the screw and unscrew the fish, coupling and uncoupling activities downhole tool such as hangers, sleeves (liners ) or activities to rotate and reciprocate the casing while you’re getting into and / or cementing.

- In wells differential sticking risk, says the arrival of the guide shoe production liner to the bottom of the well, when it is run and it is necessary to bring the shoe to the bottom of the shaft with rotation and movement, no need to lift the bottom casing to position the cementing head, as may occur when low-lung and rotation using the kelly.

- Connections are screwed and unscrewed at any level of the tower: The driller has a better control of the well to be able to connect and move the string at any height of the tower, rather than relying on a manual valve control and having to dial up and connect and swivel.

- Allows rotation and movement immediately when problems are found in the hole.

- Eliminates the dangerous quadrant disconnection procedure when NOV TDS-5H 500 Ton Top Drive is at a considerable height in the tower in case of sticking of the pipe.

Reviews

There are no reviews yet.